HVAC Performance Monitor

Moderators: grovkillen, Stuntteam, TD-er

HVAC Performance Monitor

I'm looking for advice on a ESPEasy project. I would like to monitor the performance of my HVAC system (home heating & cooling).

I need to measure Delta-T and External Static Pressure inside the air handler (air blower cabinet). This means I need to know temperature (1 degree precision) and air pressure (0.1 - 0.8 inches of water) at two places. Humidity data would be nice too.

Two 3.3V I2C BME280's on an ESP32 seem like a practical choice for this.

Some questions:

1. Any other Pressure/Temperature/Humidity sensors I should consider?

2. Anyone experience issues with eBay / aliexpress BME280 modules?

3. Has anyone achieved reliable communication on long cable lengths that connect two separate BME280 sensors to a ESP32?

Both will share the same I2C I/O pin and *each* sensor will be connected with about 1.5 meters of shielded cable.

4. Given the long cable length, would it be better to use two SPI channels instead?

Any advice appreciated.

- Thomas

I need to measure Delta-T and External Static Pressure inside the air handler (air blower cabinet). This means I need to know temperature (1 degree precision) and air pressure (0.1 - 0.8 inches of water) at two places. Humidity data would be nice too.

Two 3.3V I2C BME280's on an ESP32 seem like a practical choice for this.

Some questions:

1. Any other Pressure/Temperature/Humidity sensors I should consider?

2. Anyone experience issues with eBay / aliexpress BME280 modules?

3. Has anyone achieved reliable communication on long cable lengths that connect two separate BME280 sensors to a ESP32?

Both will share the same I2C I/O pin and *each* sensor will be connected with about 1.5 meters of shielded cable.

4. Given the long cable length, would it be better to use two SPI channels instead?

Any advice appreciated.

- Thomas

Re: HVAC Performance Monitor

You could use some I2C expander chip, which is usually only used for devices using the same address.

Or mixing 5V/3V3 devices.

But it also allows to create completely separated I2C busses with their own termination.

For really long cables, I guess you should also lower the I2C clock and start experimenting using twisted wires (pair for Vcc/SDA and Vcc/SCL) Maybe also add some capacitor over Vcc/GND at the sensor side.

You can also look into 1wire sensors as those can be on quite long cables and above all are read at the same time when put in the same task.

However this doesn't do pressure, but can be useful to see if temperature changes a lot in a short amount of time.

Another option is to use ESPeasy p2p.

You can send a command from one node to the other to perform a taskrun and let the returned value be sent back via either p2p or do some pre-processing in rules (e.g. take average over N samples)

You can also enable pluginstats (relatively new feature, see here for the latest and greatest addition to it https://td-er.nl/ESPEasy/latest/ ) and then you can do some basic operations over the last N samples. This makes it less time critical to have both exactly in sync. On the other hand, with the p2p active, the time is synced among nodes with very little time difference.

https://td-er.nl/ESPEasy/latest/ ) and then you can do some basic operations over the last N samples. This makes it less time critical to have both exactly in sync. On the other hand, with the p2p active, the time is synced among nodes with very little time difference.

One tip when trying the linked build, try using the scroll-wheel and/or shift-left-click (or pinch on the mobile)

Or simply click here to see the animated GIF: https://github.com/letscontrolit/ESPEasy/pull/5053

Or mixing 5V/3V3 devices.

But it also allows to create completely separated I2C busses with their own termination.

For really long cables, I guess you should also lower the I2C clock and start experimenting using twisted wires (pair for Vcc/SDA and Vcc/SCL) Maybe also add some capacitor over Vcc/GND at the sensor side.

You can also look into 1wire sensors as those can be on quite long cables and above all are read at the same time when put in the same task.

However this doesn't do pressure, but can be useful to see if temperature changes a lot in a short amount of time.

Another option is to use ESPeasy p2p.

You can send a command from one node to the other to perform a taskrun and let the returned value be sent back via either p2p or do some pre-processing in rules (e.g. take average over N samples)

You can also enable pluginstats (relatively new feature, see here for the latest and greatest addition to it

One tip when trying the linked build, try using the scroll-wheel and/or shift-left-click (or pinch on the mobile)

Or simply click here to see the animated GIF: https://github.com/letscontrolit/ESPEasy/pull/5053

Re: HVAC Performance Monitor

Oh and maybe you can also have a look at the BMP3xx sensors made by Bosch.

Those have a higher resolution compared to the BME280.

See: https://espeasy.readthedocs.io/en/lates ... #p154-page

Keep in mind the temperature and pressure are fixed to different filter/oversampling settings.

This means they have a different delay.

If you need this changed or at least configurable, please let me know (or change it yourself )

)

Those have a higher resolution compared to the BME280.

See: https://espeasy.readthedocs.io/en/lates ... #p154-page

Keep in mind the temperature and pressure are fixed to different filter/oversampling settings.

This means they have a different delay.

If you need this changed or at least configurable, please let me know (or change it yourself

Re: HVAC Performance Monitor

I dont have a setup to monitor the performance of my HVAC unit, but I do monitor the run times. I have relays tied in with the furnace control board. They connect to my esp8266 and I keep track of run time of the fan and ac running or heat running. I think they are 24 volt relays. I thought about using some of the DS18B20 waterproof temp sensor to monitor in and out temps but I found that the run time is all I really cared to know.

Rob

Rob

Re: HVAC Performance Monitor

Thanks for the replies. Appreciate it.

@TD-er: The BMP390 looks good. But it doesn't include humidity, which is a nice feature of their old sensor. Trying to keep this build uber simple, so adding more sensors/hardware does not appeal to me. I'll think about this and decide if losing humidity will be an issue.

@Rob73: +1, I will be using a little 4-channel opto board to detect the state of the three different blower speeds (cool, heat, fan). The control voltages are 24VAC, so safe stuff to tap into.

- Thomas

@TD-er: The BMP390 looks good. But it doesn't include humidity, which is a nice feature of their old sensor. Trying to keep this build uber simple, so adding more sensors/hardware does not appeal to me. I'll think about this and decide if losing humidity will be an issue.

@Rob73: +1, I will be using a little 4-channel opto board to detect the state of the three different blower speeds (cool, heat, fan). The control voltages are 24VAC, so safe stuff to tap into.

- Thomas

Re: HVAC Performance Monitor

Not 100% what you try to measure.

Will the sensor come into direct contact with something that can cause condensation? (or freezing?)

Or is there something blowing directly into the sensor?

Do you have some links for me to read into?

Edit:

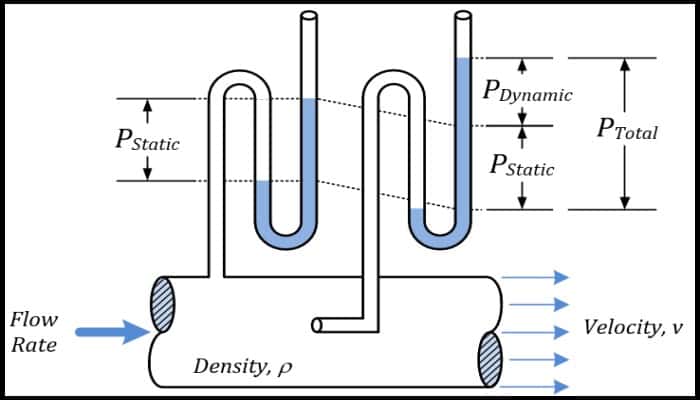

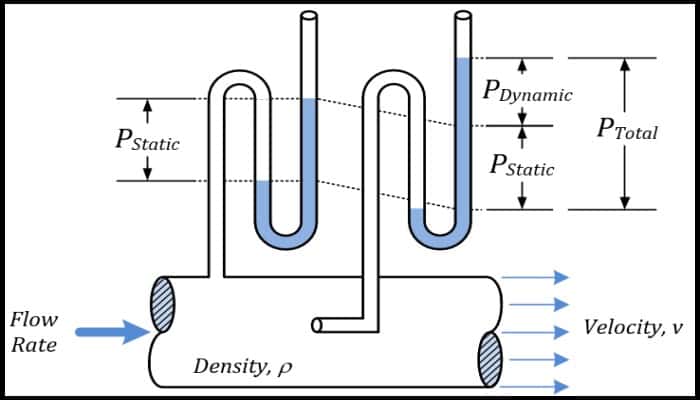

Found this one online, which may be easier to have some "talking picture" ("praatplaatje" in Dutch )

)

(Source:)

I assume you plan on doing something similar.

But then I wonder if it is useful to have the temperature/humidity measured in the same spot as where you measure the pressure.

Will the sensor come into direct contact with something that can cause condensation? (or freezing?)

Or is there something blowing directly into the sensor?

Do you have some links for me to read into?

Edit:

Found this one online, which may be easier to have some "talking picture" ("praatplaatje" in Dutch

(Source:)

I assume you plan on doing something similar.

But then I wonder if it is useful to have the temperature/humidity measured in the same spot as where you measure the pressure.

Re: HVAC Performance Monitor

My HVAC is a typical USA furnace design. The gas furnace / air handler is a packaged unit that is in the attic. It includes the air blowing fan, heat exchanger, and AC evaporator coil for cooling. The AC condenser is located outdoors.

The goal is to measure Delta-T and external static pressure measurements. These are common HVAC measurements. Both are measured inside the furnace air handler cabinet. Realtime measurements will allow me to send notifications if my air filters and/or evaporator coil are dirty or other system issues are occurring.

For example, here is a video of a HVAC tech performing the external static pressure measurement on a furnace similar to mine:

https://www.youtube.com/watch?v=wHeOe06z70w

I also thought it would be interesting to measure humidity before and after the evaporator coil to monitor de-humidification. This is not a critical requirement in my project, just a bonus feature if I can do it without additional hardware. This would be a relative measurement reported in percent.

- Thomas

The goal is to measure Delta-T and external static pressure measurements. These are common HVAC measurements. Both are measured inside the furnace air handler cabinet. Realtime measurements will allow me to send notifications if my air filters and/or evaporator coil are dirty or other system issues are occurring.

For example, here is a video of a HVAC tech performing the external static pressure measurement on a furnace similar to mine:

https://www.youtube.com/watch?v=wHeOe06z70w

I also thought it would be interesting to measure humidity before and after the evaporator coil to monitor de-humidification. This is not a critical requirement in my project, just a bonus feature if I can do it without additional hardware. This would be a relative measurement reported in percent.

- Thomas

Re: HVAC Performance Monitor

Hmm I have to do some reading I guess as "gas furnace" sounds like something that's producing heat.

And measuring humidity in some air of different temperature is quite hard to compare.

So that's probably a wrong assumption of mine and thus I need to start catching up on this topic

I thought it would be just some compressor, like our heatpump systems here (I have an AC which can also heat and a heatpump central heating)

Just like how a refridgerator or freezer works.

And measuring humidity in some air of different temperature is quite hard to compare.

So that's probably a wrong assumption of mine and thus I need to start catching up on this topic

I thought it would be just some compressor, like our heatpump systems here (I have an AC which can also heat and a heatpump central heating)

Just like how a refridgerator or freezer works.

Re: HVAC Performance Monitor

Hmm on that video they use tubes to get the 2 measuring points for static and dynamic pressure to a central point.

Why can't you do this too? This way you don't need to have the I2C sensors far apart.

Why can't you do this too? This way you don't need to have the I2C sensors far apart.

Re: HVAC Performance Monitor

Yup, I also realized that probes attached with tubing will prevent any I2C issues.

I already have the static pressure probes (and silicon tubing). They're for my manometer and I don't want to dedicate them to this project. But to save costs, I suspect I can replicate the probes with hobby shop brass tubing. I will do some testing.

Edit: I can't mount the sensors with the silicone hose method. I also want to measure air temperature with the same sensors, so they need to be in the actual air path.

I've decided to use the BMP390 temperature/pressure sensors and skip humidity measurements. I will order some breakout type boards from Aliexpress and try them out.

Thanks for your comments. It's good to have someone to bounce ideas off to see what sticks.

- Thomas

I already have the static pressure probes (and silicon tubing). They're for my manometer and I don't want to dedicate them to this project. But to save costs, I suspect I can replicate the probes with hobby shop brass tubing. I will do some testing.

Edit: I can't mount the sensors with the silicone hose method. I also want to measure air temperature with the same sensors, so they need to be in the actual air path.

I've decided to use the BMP390 temperature/pressure sensors and skip humidity measurements. I will order some breakout type boards from Aliexpress and try them out.

Thanks for your comments. It's good to have someone to bounce ideas off to see what sticks.

- Thomas

Last edited by ThomasB on 19 Jun 2024, 17:27, edited 1 time in total.

Re: HVAC Performance Monitor

Hmm apparently your question completely messed up my "YouTube Algorithm" selection.

So came across this one and maybe a cheap and easy tip (pun intended... twice ) for you: https://youtu.be/6uMqw69XkRw?t=204

) for you: https://youtu.be/6uMqw69XkRw?t=204

So came across this one and maybe a cheap and easy tip (pun intended... twice

Re: HVAC Performance Monitor

Oh and another question... Does the BMP390 have enough pressure range for this measurement?

Re: HVAC Performance Monitor

The external static pressure is nominally 0.5 inches (water column). In the wild it can typically range from 0.2 to 0.9 inches, but such extreme values would indicate a system needing maintenance.

The furnace manual contains a table of "calibrated" static pressure values that range from 0.1 to 1.0 inches for the cooling and heating modes. The technician consults this data table to see if the system has proper air flow (CFM). Basically the data table converts the blower's motor speed and the measured static pressure to CFM.

The BMP390 appears to have the resolution and range I need. But I've been wrong many times before.

- Thomas

The furnace manual contains a table of "calibrated" static pressure values that range from 0.1 to 1.0 inches for the cooling and heating modes. The technician consults this data table to see if the system has proper air flow (CFM). Basically the data table converts the blower's motor speed and the measured static pressure to CFM.

The BMP390 appears to have the resolution and range I need. But I've been wrong many times before.

- Thomas

Re: HVAC Performance Monitor

Let's first convert it to something I can understand as we for sure do have water here, but rarely in a column (an inch in height difference is called a "hill" or maybe a mountain here) and also those inches are something I can't get used to

1 inch of water column to mbar = 2.49089 mbar

According to this site: https://www.convertunits.com/from/inch% ... mn/to/mbar

So that should for sure be within range of the sensor, given you need to add the normal air pressure to it (1000-ish mbar at "the Netherlands level" ehh "below sealevel")

Anyway if your extremes are plus or minus 2.49 mbar, I do get it why you would opt for the BMP388 or BMP390 due to their much higher resolution.

1 inch of water column to mbar = 2.49089 mbar

According to this site: https://www.convertunits.com/from/inch% ... mn/to/mbar

So that should for sure be within range of the sensor, given you need to add the normal air pressure to it (1000-ish mbar at "the Netherlands level" ehh "below sealevel")

Anyway if your extremes are plus or minus 2.49 mbar, I do get it why you would opt for the BMP388 or BMP390 due to their much higher resolution.

Re: HVAC Performance Monitor

It is funny how each industry (and country) has their preferred units of measure that is different from others. The USA is typically PSI for gases and liquid pressures, but littered with variations that have been adopted by our mechanical trades.

- Thomas

- Thomas

Re: HVAC Performance Monitor

I have worked for a ship design company (responsible for everything somewhat electrical  )

)

The most confusing unit of measure I have seen there was metric tonne per cubic feet.

Well it isn't that odd when you consider containers to be measured in foot and tonnes (weight) also have a nice round ratio to volume of water (in cubic meters).

And for ships it is apparently important to know how much water will be displaced to keep floating.

But still it is rather confusing at first to see imperial units and metric units in the same unit of measure.

Hard to fathom

The most confusing unit of measure I have seen there was metric tonne per cubic feet.

Well it isn't that odd when you consider containers to be measured in foot and tonnes (weight) also have a nice round ratio to volume of water (in cubic meters).

And for ships it is apparently important to know how much water will be displaced to keep floating.

But still it is rather confusing at first to see imperial units and metric units in the same unit of measure.

Hard to fathom

Re: HVAC Performance Monitor

"Hard to fathom." I see what you did there.

BTW, the pressure tubing idea is a no-go. The BMP390 needs to be in the air stream because it will be used to provide temperature too. So back to worrying about I2C cable lengths.

- Thomas

BTW, the pressure tubing idea is a no-go. The BMP390 needs to be in the air stream because it will be used to provide temperature too. So back to worrying about I2C cable lengths.

- Thomas

Re: HVAC Performance Monitor

Thanks for all the advice.

I've decided to use a single ESP32 with the TCA9548A I2C multiplexer plugin. This will allow each sensor to have its own I2C channel. I'll use 5V logic levels to the sensors since the TCA9548A and BMP390 modules support doing that.

I also decided to add a third BMP390. There will be one before the blower fan, one after it, and a third after the A-coil condenser. This will allow measuring external static pressure, as well as detect when the A-coil needs cleaning. And of course the Delta-T measurements for heating and cooling.

The schematic is nearly complete and parts have been ordered from AliExpress.

- Thomas

I've decided to use a single ESP32 with the TCA9548A I2C multiplexer plugin. This will allow each sensor to have its own I2C channel. I'll use 5V logic levels to the sensors since the TCA9548A and BMP390 modules support doing that.

I also decided to add a third BMP390. There will be one before the blower fan, one after it, and a third after the A-coil condenser. This will allow measuring external static pressure, as well as detect when the A-coil needs cleaning. And of course the Delta-T measurements for heating and cooling.

The schematic is nearly complete and parts have been ordered from AliExpress.

- Thomas

Re: HVAC Performance Monitor

So an I2C level converter is part of the plan? You're ESP32 (shouldn't be buying ESP8266s these days) won't live long with 5V applied to the GPIOs

/Ton (PayPal.me)

Re: HVAC Performance Monitor

The multiplexer does separate the input I2C bus (on ESP side) and any of the selectable output busses.

So each of those output busses can in theory use their own voltage level.

@ThomasB

Make sure to use pull-up resistors on each I2C bus, so on the ESP32 side as well as on each selectable port of the multiplexer.

Re: HVAC Performance Monitor

Yeah, but AFAIR they only have a single power source, so they expect the same signal levels on all sides, and 3V3 high is just barely high enough for a 5V input, making it rather unstable/sensitive.

/Ton (PayPal.me)

Re: HVAC Performance Monitor

Since the pull-up resistors are kinda required, you could argue the chip only needs to pull the line down to switch logic levels.

So the chip should not need to source a voltage higher than its input. It only needs to be 5V tolerant and being able to sink (thus connect to GND) fast enough.

Here the datasheet: https://www.ti.com/lit/ds/symlink/tca9548a.pdf

So the chip should not need to source a voltage higher than its input. It only needs to be 5V tolerant and being able to sink (thus connect to GND) fast enough.

Here the datasheet: https://www.ti.com/lit/ds/symlink/tca9548a.pdf

I don't see yet that it does require a Vcc higher than the signal levels.Allows voltage-level translation between 1.8-V,

2.5-V, 3.3-V, and 5-V buses

Re: HVAC Performance Monitor

That's the part that worries me, on the ESP side. ESP8266 is quite 5V tolerant on the GPIOs, but ESP32 doesn't handle that very well, AFAIK.

/Ton (PayPal.me)

Re: HVAC Performance Monitor

I mean on the output bus of the multiplexer.

Re: HVAC Performance Monitor

The mixed logic levels are described on the data sheet, as follows:

The TCA9545A will be powered with 3.3VDC. The external I2C pull-ups set the logic high levels for the ESP32 and each peripheral. This allows mixing 3.3V with a 5V bus.

- Thomas

The TCA9545A will be powered with 3.3VDC. The external I2C pull-ups set the logic high levels for the ESP32 and each peripheral. This allows mixing 3.3V with a 5V bus.

- Thomas

Re: HVAC Performance Monitor

Yeah, I'll just leave the hardware to the hardware guys

/Ton (PayPal.me)

Re: HVAC Performance Monitor

I read some reviews about the Adafruit LTC4311 I2C Extender/Active Terminator board. This $10 USD module allows long I2C cable lengths. One user claimed success with 30 feet of UTP cable! Holy Moly.

There's also the cheap ($1 USD) PCA9515A I2C Repeater Module on AliExpress. When installed at the center of a cable it can double the usable cable length. This might provide the one meter length I need. Will try it out.

Still a bit worried about the high temperature one of the BMP390 sensors will need to endure. It will be close to the gas fired heat exchanger. I haven't measured it yet, but I'm predicting air temperature will exceed 140°F (60°C). That's within the operating temp of the sensor IC, but the Chinese made module board might not like it long term. Will use the pressure tube method on this sensor, if necessary.

TL;DR My I2C cable length concerns have been demoted to DEFCON 5.

- Thomas

There's also the cheap ($1 USD) PCA9515A I2C Repeater Module on AliExpress. When installed at the center of a cable it can double the usable cable length. This might provide the one meter length I need. Will try it out.

Still a bit worried about the high temperature one of the BMP390 sensors will need to endure. It will be close to the gas fired heat exchanger. I haven't measured it yet, but I'm predicting air temperature will exceed 140°F (60°C). That's within the operating temp of the sensor IC, but the Chinese made module board might not like it long term. Will use the pressure tube method on this sensor, if necessary.

TL;DR My I2C cable length concerns have been demoted to DEFCON 5.

- Thomas

Re: HVAC Performance Monitor

Well if you have hot air, there will probably be no condensation.

Maybe also paint some nail polish on the solder joints.

I would not be too worried about the I2C cable lenght when using an I2C port multiplexer.

Just use a twisted pair for SDA/Vcc and one for SCL/Vcc and place some capacitor over Vcc/GND close to the sensor. (100 nF to start with)

You can lower the clock frequency to nearly DC, so that's also not really a problem.

I have run I2C sensors here on the most horrible 60cm Dupont wires you can imagine at 100 kHz and then 2 of those daisy-chained.

Also you do know how my desk looks like, so not really "clean signals".

And just so you know, I just changed the ESPEasy p2p protocol so now sending takes way less effort and the timestamp of the sent value is included.

So on the receiving node you can just compare values, based on the time the sample was taken. Next few days I will add a proper interpolation function so you can just ask for the average over a given time period (e.g. last 15 seconds, even though the task samples every 10 seconds)

N.B. the chart may show a strange uptime, but that was while testing formula fields, like "%value%*1.024", which still has a bug when using p2p with formulas.... working on it

Maybe also paint some nail polish on the solder joints.

I would not be too worried about the I2C cable lenght when using an I2C port multiplexer.

Just use a twisted pair for SDA/Vcc and one for SCL/Vcc and place some capacitor over Vcc/GND close to the sensor. (100 nF to start with)

You can lower the clock frequency to nearly DC, so that's also not really a problem.

I have run I2C sensors here on the most horrible 60cm Dupont wires you can imagine at 100 kHz and then 2 of those daisy-chained.

Also you do know how my desk looks like, so not really "clean signals".

And just so you know, I just changed the ESPEasy p2p protocol so now sending takes way less effort and the timestamp of the sent value is included.

So on the receiving node you can just compare values, based on the time the sample was taken. Next few days I will add a proper interpolation function so you can just ask for the average over a given time period (e.g. last 15 seconds, even though the task samples every 10 seconds)

N.B. the chart may show a strange uptime, but that was while testing formula fields, like "%value%*1.024", which still has a bug when using p2p with formulas.... working on it

Re: HVAC Performance Monitor

Thanks for the tips.

Today I crawled back into the attic to review the installation. Appears I will have three different I2C cable lengths that range from 1m to 2.5m.

I also saw that the HVAC contractor installed my evaporator coil in such a way that cleaning it will cost a fortune. No way to access it without a significant amount of labor. I hate new home construction, so many shortcuts are taken and build quality is dismal.

I thought my HVAC system was out of warranty. But I checked and it is valid to Feb-2025. So I have time to experiment and won't do a permanent installation until then.

- Thomas

Today I crawled back into the attic to review the installation. Appears I will have three different I2C cable lengths that range from 1m to 2.5m.

I also saw that the HVAC contractor installed my evaporator coil in such a way that cleaning it will cost a fortune. No way to access it without a significant amount of labor. I hate new home construction, so many shortcuts are taken and build quality is dismal.

I thought my HVAC system was out of warranty. But I checked and it is valid to Feb-2025. So I have time to experiment and won't do a permanent installation until then.

- Thomas

Re: HVAC Performance Monitor

Hmm that looks like quite a large installation.

My complete heatpump installation including metal housing to shield against the weather is about the size of what you have as "Furnace". It is also mounted outside on the roof, so you don't see it at all inside the house.

Sure it also has some boiler vat with 200 liter warm water one floor down, which looks like a large fridge.

And all the airco tubing from the indoor units to the central outdoor unit is fed through a 10x5 cm pipe/tube.

Quite a big size difference.

Those really massive tubes and pipes all throughout your house really sound like a pain to place furniture etc.

My complete heatpump installation including metal housing to shield against the weather is about the size of what you have as "Furnace". It is also mounted outside on the roof, so you don't see it at all inside the house.

Sure it also has some boiler vat with 200 liter warm water one floor down, which looks like a large fridge.

And all the airco tubing from the indoor units to the central outdoor unit is fed through a 10x5 cm pipe/tube.

Quite a big size difference.

Those really massive tubes and pipes all throughout your house really sound like a pain to place furniture etc.

Re: HVAC Performance Monitor

No impact to furniture placement. The conditioned air is routed to each room via ceiling mounted registers. So all the air ducts are contained in the attic. Only crazy people go up there. {People like me.}

- Thomas

- Thomas

Re: HVAC Performance Monitor

Crawled back into the attic and performed more external static pressure measurements on the furnace. I confirmed that the pressure probe construction is not critical; A scrap piece of 3/16" hobby tubing worked as well as my commercially made probes:

High-end residential HVAC systems are capable of reporting the data that I want to see. Here is a screenshot of such a system (found via random search on the interwebs).

- Thomas

High-end residential HVAC systems are capable of reporting the data that I want to see. Here is a screenshot of such a system (found via random search on the interwebs).

- Thomas

Re: HVAC Performance Monitor

Well the "N/A" part has already been implemented, and I guess the top one is also matching your setup.

So you're already halfway done

How is the airflow measured? Just some integration time period over the measured RPM and multiplied with some constant value? (I doubt it will be a linear function of the RPM though)

So you're already halfway done

How is the airflow measured? Just some integration time period over the measured RPM and multiplied with some constant value? (I doubt it will be a linear function of the RPM though)

Re: HVAC Performance Monitor

Found this helpful YT for a cheap HVAC sensor: https://www.youtube.com/watch?v=RFVD462rZio

It uses 2 BME680s, that (also) provides humidity, and is supported by ESPEasy. The ESPHome part can be replaced 1:1 by ESPEasy, IMHO

It uses 2 BME680s, that (also) provides humidity, and is supported by ESPEasy. The ESPHome part can be replaced 1:1 by ESPEasy, IMHO

/Ton (PayPal.me)

Re: HVAC Performance Monitor

For your pressure measurements what about something like the XGZP6899A air gas Differential pressure sensor? A quick web search for 3.3 volt differential pressure sensor brought it up. But apparently there are a bunch of variants of these differential pressure sensors that may be what you could use to measure your pressures and they seem to be in the low price ranges. Looks like there are also some Digital Barometric Pressure Sensor Modules, about 3 bucks, that spit out a simple analog signal also.

Rob

Rob

Re: HVAC Performance Monitor

@TD-er: Determining the airflow (CFM) is one of the reasons for measuring the external static pressure. The furnace manual has a table that provides the actual airflow (CFM) value based on blower motor speed and external static pressure. Ideally there would be an equation for this, but it looks like I will need to use the table lookup method instead.

The furnace blower is fixed speed and uses an ECM motor (constant RPM) which makes things simple. The motor speed is different for cool, heat, and air-circulation (fan) mode. But they are constant values.

@Ath: Your link to the HVAC project is a good example of what I want to do. The video shows the displayed data is calculating the static pressure (inWC reading). I need to do that too. But I could not find the sensor's conversion math in the links the author provided. But I assume it is just a matter of multiplying the ESPEasy's pressure reading by 0.4014742133.

@Rob73: Thanks for the tip. I decided to try out the BMP390. AliExpress has my money.

- Thomas

The furnace blower is fixed speed and uses an ECM motor (constant RPM) which makes things simple. The motor speed is different for cool, heat, and air-circulation (fan) mode. But they are constant values.

@Ath: Your link to the HVAC project is a good example of what I want to do. The video shows the displayed data is calculating the static pressure (inWC reading). I need to do that too. But I could not find the sensor's conversion math in the links the author provided. But I assume it is just a matter of multiplying the ESPEasy's pressure reading by 0.4014742133.

@Rob73: Thanks for the tip. I decided to try out the BMP390. AliExpress has my money.

- Thomas

Re: HVAC Performance Monitor

Any chance there is a SPI based BMP3xx plugin in the wild? Even if experimental. SPI (instead of I2C) would simplify my hardware.

- Thomas

- Thomas

Re: HVAC Performance Monitor

Maybe Excel can compute a trend formula for you when you enter the "lookup table" values in Excel.

I expect it will be some kind of sin^2 shape curve (0 ... 90 degree part) where it will hardly see extra airflow at low RPM and at some point it will hit the limit of how much air you can pass through regardless of how much extra pressure you will add.

And I guess the change of such a limit is exactly what you would like to measure, right?

I expect it will be some kind of sin^2 shape curve (0 ... 90 degree part) where it will hardly see extra airflow at low RPM and at some point it will hit the limit of how much air you can pass through regardless of how much extra pressure you will add.

And I guess the change of such a limit is exactly what you would like to measure, right?

Re: HVAC Performance Monitor

Not yet, but maybe I know someone who can help you to prepare a pull request

Re: HVAC Performance Monitor

I think what you are saying is that reducing my hardware work means I have to do more software work. I was hoping an ESPEasy dev had already created it.Not yet, but maybe I know someone who can help you to prepare a pull request

Too bad ChatGPT can't help me out.

- Thomas

Re: HVAC Performance Monitor

I've reserved plugin P172 for the SPI variation of P154 for BME3XX  Most of the P154 code can be reused, so should be a low-impact change...

Most of the P154 code can be reused, so should be a low-impact change...

Somewhat similar to the integration of P020 and P044, where the code is in the P020 source files, with an extra variable to determine which plugin is actually used.

Somewhat similar to the integration of P020 and P044, where the code is in the P020 source files, with an extra variable to determine which plugin is actually used.

Last edited by Ath on 22 Jun 2024, 21:44, edited 1 time in total.

/Ton (PayPal.me)

Re: HVAC Performance Monitor

Nice! I know a guy that would be able to test it.

And speaking of SPI, what is the latest favorite 2.8" - 3.5" Color LCD for use with ESPEasy?

I have a 2.4" ILI9341 based panel sitting in a drawer. But I don't mind ordering something bigger and better. Don't need touch feature, just want a color panel with good brightness.

- Thomas

Re: HVAC Performance Monitor

If the brightness and size of that panel is of your liking, then just use that. There hasn't been much innovation in that area, other than size. The graphics features we have are available for all supported TFT displays.ThomasB wrote: ↑22 Jun 2024, 21:43 And speaking of SPI, what is the latest favorite 2.8" - 3.5" Color LCD for use with ESPEasy?

I have a 2.4" ILI9341 based panel sitting in a drawer. But I don't mind ordering something bigger and better. Don't need touch feature, just want a color panel with good brightness.

Looked at the SPI features of the BME3XX library, and it does fiddle a bit with the SPI settings, so not sure if that might affect something (most likely the update speed), but you'll be testing that yourself, probably

/Ton (PayPal.me)

Re: HVAC Performance Monitor

Have you actually tried using I2C over long cables using just any sensor or display you have laying around?

For a number of sensor types I really understand why SPI could be beneficial because of its higher speed. But not for a pressure sensor. (at least not how it is going to be used here)

And I really doubt using a (significantly) higher frequency bus is going to help you covering a longer distance. Especially when you also need to split it into some Y-shape bus.

Re: HVAC Performance Monitor

Mine is only 2.4". AliExpress has IPS HD 3.5 inch SPI (ILI9488) panels for under $9 USD. So I put one in my cart for a future order.If the brightness and size of that panel is of your liking, then just use that.

I've used I2C on long cables (>.5m) on other projects. Sometimes regretted it due to the cable gremlins. Success required experimentation (custom selected terminations, revised cable layouts, and other witchcraft) to get reliable data. But this is not the only reason for moving to SPI.Have you actually tried using I2C over long cables using just any sensor or display you have laying around?

In my case I need three BMP390 sensors. But they only support two addresses. So with I2C I am obligated to use a TCA9548A I2C multiplexer chip. Yes I can solder and have ordered the multiplexer chips, but SPI makes life simpler.For a number of sensor types I really understand why SPI could be beneficial because of its higher speed.

- Thomas

Re: HVAC Performance Monitor

The I2C multiplexer also makes the longer bus issues much less of an issue as you literally split your bus into new busses after the multiplexer.

Re: HVAC Performance Monitor

The ILI9488 displays are a real PITA, software-wise, so better get an ILI9341/ILI9481/ILI9486 (P095) or ST77xx (P116) display unit.

/Ton (PayPal.me)

Re: HVAC Performance Monitor

Yup, that's a benefit of the I2C multiplexer chip. Would likely have needed it even if I only had two BMP390's.The I2C multiplexer also makes the longer bus issues much less of an issue as you literally split your bus into new busses after the multiplexer.

Thanks for the tip. I will get back on AliExpress and change my panel choice.The ILI9488 displays are a real PITA, software-wise, so better get an ILI9341/ILI9481/ILI9486 (P095) or ST77xx (P116) display unit.

- Thomas

Re: HVAC Performance Monitor

Just tested a 2m cable with I2C sensor attached to it.

Working just fine at 400 kHz

Working just fine at 400 kHz

Who is online

Users browsing this forum: No registered users and 11 guests